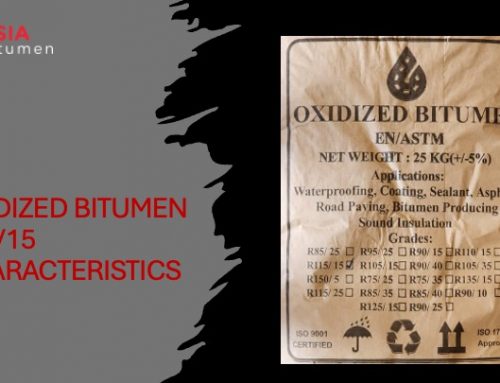

Oxidized Bitumen 115/15 packing would be very important and must have these properties:

Packing must be heat resistant when we are filling in the factory

Bags weight must be 25 kg for better handling and use in the production lines of factories

Oxidized bitumen 115/15 must separate from bags very easily and clearly

The bags must fill in one poly amid bag when oxidized bitumen is hot and when it became cold in the water pool put in 25 kg PP bags for avoiding leakage in containers.

One of the important items is that the inner packing of oxidized bitumen must be Polyamide bags because it can melt inside the mixers of waterproof membrane factories and asphalt factories also it will help them to use it directly in the production line without wasting time, and energy and extra charges fee for separating the polyamide bags from Oxidized Bitumen 115/15, Polyamide would be an example of semi-crystalline polymers in which the amide group is placed in the form of a polymer chain Also, due to having hydrogen bonds, they have extraordinary strength. Polyamide is meltable and melts at a temperature of 90 degrees Celsius.

Also, this polyamide is a very suitable option for packing types of oxidized bitumen due to its high resistance to petroleum solvents, high abrasion, and impact resistance against successive bending.

We placed our oxidized bitumen 115/15 packing video here for our clients to find that how our packings are according to the international standards for exporting to the whole of the world.

Thanks it was very helpful

You are Welcome Sir

👍👍

Hello Asia Bitumen

This is good condition packing 👌

Thanks for sharing