What is Oxidized Bitumen

Oxidized Bitumen producing process

Oxidized bitumen is blown from blowing hot air to pure bitumen at the final stage of the purification operation In this process, hot air with a temperature of 200 to 300 degrees Celsius is blown through a perforated tube into a compartment containing bitumen.

As a result of this process, the hydrogen atoms in the bituminous hydrocarbon molecules are combined with air oxygen and the polymerization takes place with the formation of water

Oxidized bitumen penetration is lower than pure bitumen

It has a higher degree of softness and a lower sensitivity to temperature variations This type of bitumen is used to make roofing sheets, car tires and lining.

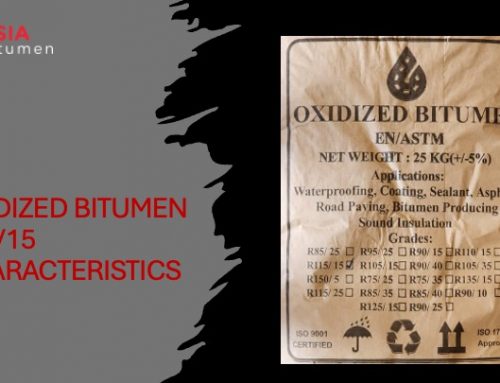

Oxidized bitumen Symbolic is R. For example R 80/25 bitumen means blown bitumen with degree of softness 80 centigrade and a degree of penetration is 25

Oxidized Bitumen uses

Oxidized Bitumen have different usages in different type industries so we will mention some of important applications of Oxidized Bitumen for you in this articles, Oxidized Bitumen in Gas and Oil industries would be using as coating materials for pipe lines and pipe joints of Oil And Gas Pipeline, lines, in electrical industries Oxidized Bitumen would be use as sealant of wire coating, blown bitumen is using in waterproofing industries too like building roofing felts in factories and first materials components who are producing waterproofing roofing felt sheets, Oxidized Bitumen is using in Bitumen and Asphalt factories for producing different grade of Bitumen and Asphalt for road paving at least one of the other usages of Oxidized Bitumen would be in sound dampen layer it is using as one of important materials for making Sound insulation layers.

great information.. thanks for sharing in this platform

your welcome sir

dear sir,good days to you, i want to build oxidation tower to oxidize vacuum residue and produce bitumen 60/70 and bitumen 80/100 would you pls. help me in the tower design

with all my regards

eng.mohammad yousef shehab

27/3/2020

my mobile whatsup is 00962799133181

Dear Mohammad

Sure we will forward your number to the Asia Bitumen engineer team to contact you.

Thanks for this information , I need steps of oxidation bitumen .

Your Welcome Sir,

Sure we will make an article about this item and will place on our bitumen factory website